Selection of Correct RTDs For Your Sensing Application

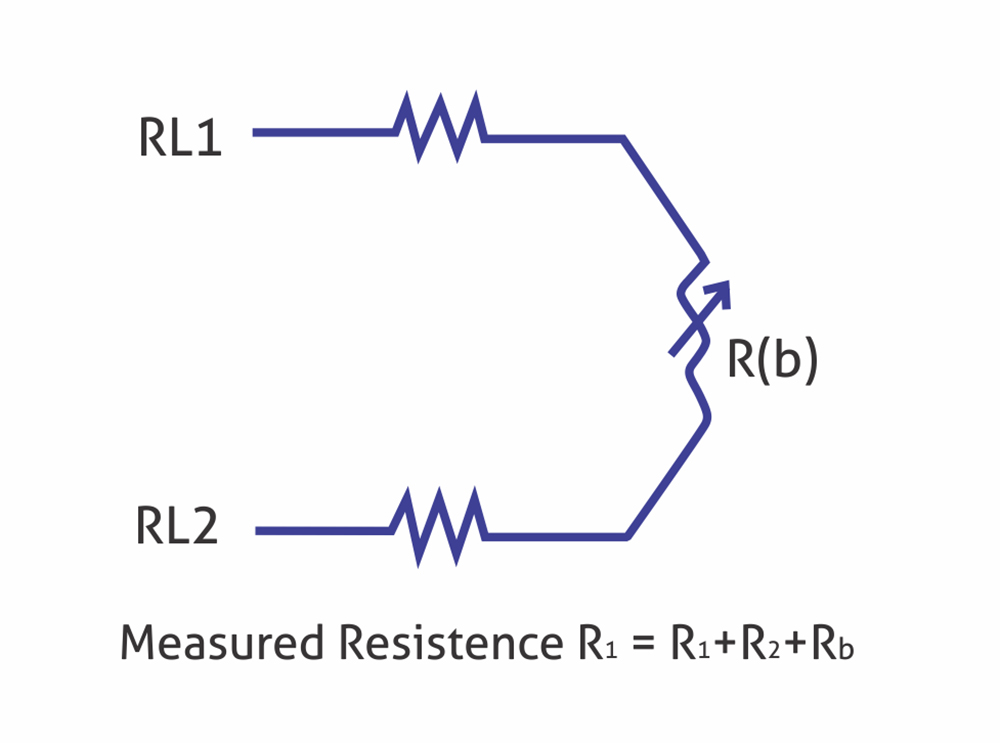

2 – Wire RTD

- Low accuracy

- Measurement errors

- Less expensive

- Connecting wires should not be lengthy

- Simplest circuit design

- A single lead wire connects to each end of the element

- The resistance in the circuit is calculated by measuring the resistance in the lead wires and connectors

- This results in some degree error or readout that is higher than the actual measured temperature. This can be eliminated with calibration

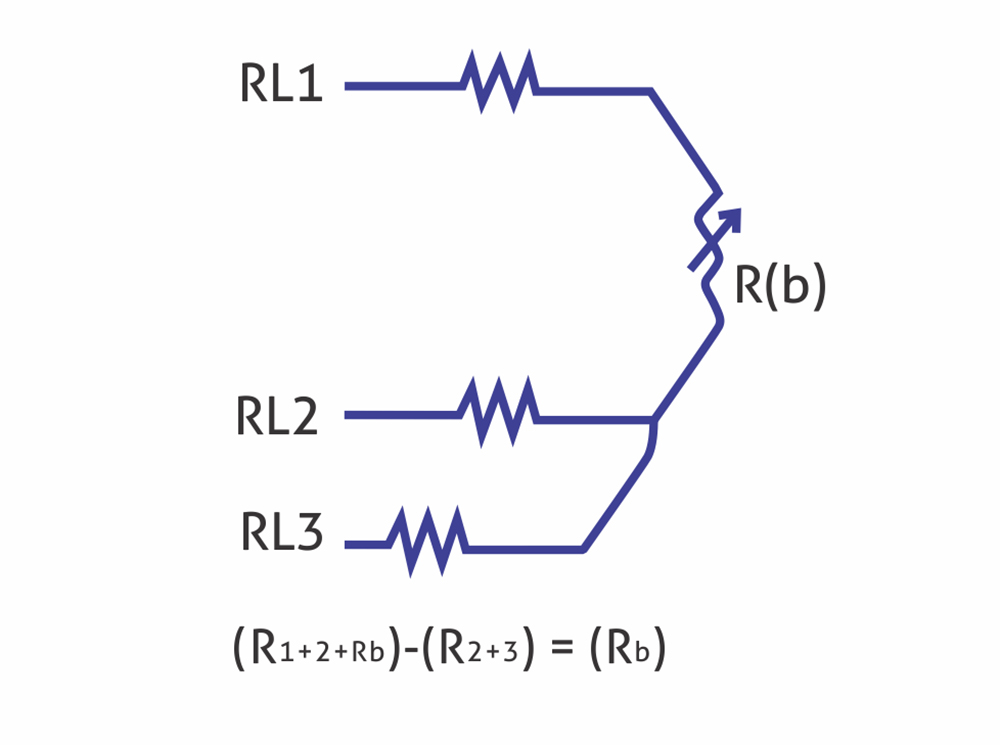

3 – wire RTD

- Better accuracy than 2 -wire

- Fewer errors

- Less expensive than the 4 wire

- The wires which are used should have the same length, Long connecting wires can be used

- The three wire configuration is the most used in industrial applications

- Two wires are connected to one end of the sensor, RL2 and RL3, and to the monitoring device. The third wire, RL1, is connected to the element

- The three wires are of equal length, so their resistance is equal

- The 2-wire configuration also has errors that have to be adjusted by calibration.

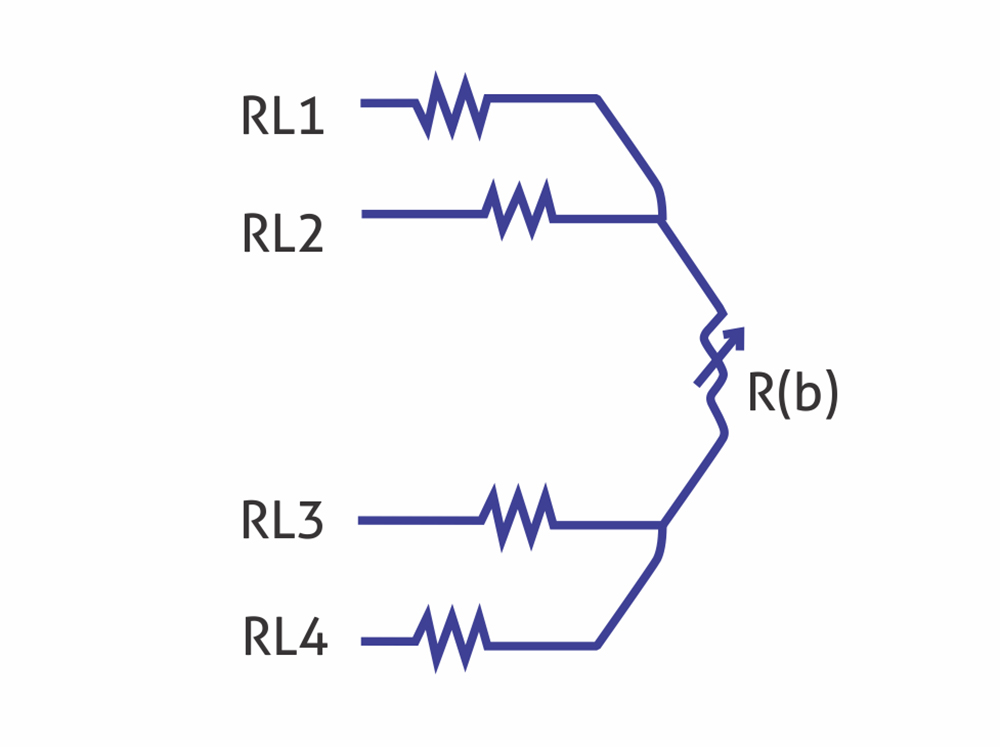

4- wire RTD

- High accuracy

- Won’t be any error

- Very expensive

- Long connecting wires can be used

- The four wire configuration is the most complex

- DC current is provided through two leads, RL1 and RL4. The voltage drop is measured by the other two leads, RL2 and RL3.

- The voltage drop and current are known, making the resistance easy to read as well as the temperature across the system.

- The 4-wire configuration is time consuming, and expensive to install but produces the most accurate and precise readings.

Waman Sanap is the CEO of iPAC Automation, a leading instrumentation and control automation company. He has 20+ years of experience in the instrumentation engineering field.