iPAC Automation - Global Instrumentation Designing Company

Global Instrumentation and Control Engineering Service Provider

ipac Automation Services

Instrumentation Detail Engineering

Smart Plant Instrumentation (SPI) Services | SPI InTools Training

Safety Integrity Level (SIL) Verification Services

Electrical Detail Engineering

Piping Detail Engineering

PLC and DCS

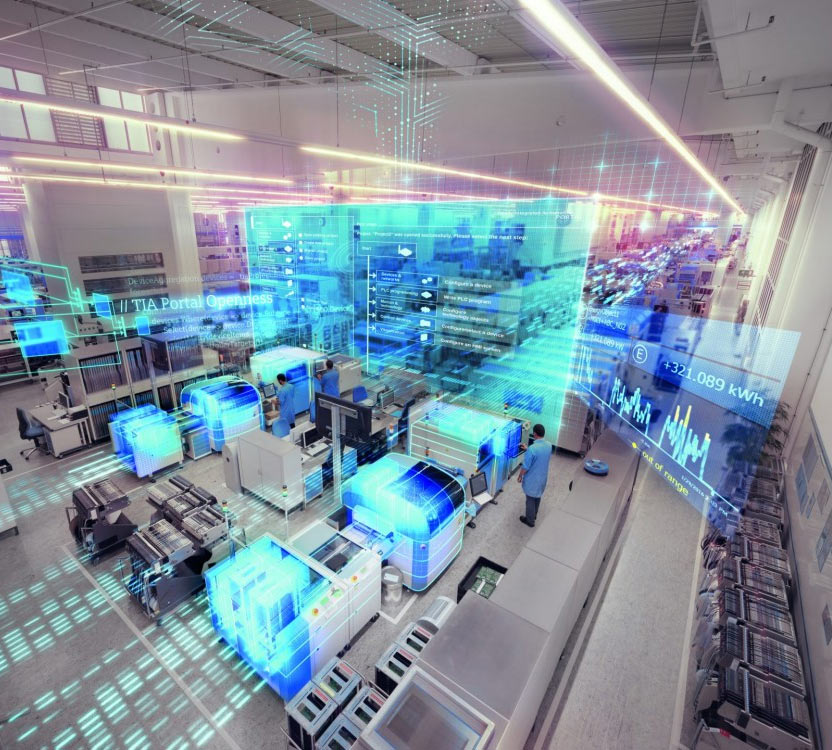

Factory Automation Services

Building Management System (BMS)

Commissioning and Site Support Services

iPAC Automation: Your Source for Expert Instrumentation & Control Automation Engineering Services

Projects Stories

Take a look at our milestones through stories

Detail Engineering

Field instrumentation detailing & designing, control systems & Commissioning for one of the leading Oil & Gas industry from Kuwait.

Migration/Reverse Engineering

FEED Drawing development to system implementation and commissioning as per existing PLC’s & drawings.

Instrumentation & SIL 3 Consultancy

SIL verification in exSILentia software & SRS documentation preparation for one of the leading EPC from Texas USA.

Core Value Proposition for our customers

“SINCERELY” completing projects with our technical expertise within the time

Delivering error proof services

“Serving cost consciously”

Industries we serve

iPAC has extensive experience in the oil and gas industry, with a focus on the upstream sector.They have provided instrumentation and control automation services for a variety of projects, including:

- New field development projects

- Brownfield revamps

- Production optimization projects

- Safety and environmental improvement projects

iPAC has a long history of providing instrumentation and control automation services for the power generation industry. They have worked on a variety of projects, including:

- New power plant construction projects

- Power plant retrofits and upgrades

- Turbine control systems

- Generator control systems

- Boiler control systems

iPAC has a strong track record of providing instrumentation and control automation services for the water treatment industry. They have worked on a variety of projects, including:

- New water treatment plant construction projects

- Water treatment plant upgrades and retrofits

- Desalination plant control systems

- Wastewater treatment plant control systems

iPAC has a wealth of experience in providing instrumentation and control automation services for building management systems. They have worked on a variety of projects, including:

- New building BMS projects

- BMS retrofits and upgrades

- BMS integration with other systems

- BMS commissioning and testing

iPAC has a proven track record of providing instrumentation and control automation services for the automotive industry. They have worked on a variety of projects, including:

- New car manufacturing plant construction projects

- Car manufacturing plant upgrades and retrofits

- Engine control systems

- Transmission control systems

- Robotic assembly lines

iPAC has a strong understanding of the unique requirements of the pharmaceutical industry. They have provided instrumentation and control automation services for a variety of projects, including:

- New pharmaceutical plant construction projects

- Pharmaceutical plant upgrades and retrofits

- Cleanroom automation

- Sterilisation systems

- Drug manufacturing systems

iPAC has a wealth of experience in providing instrumentation and control automation services for the brewing industry. They have worked on a variety of projects, including:

- New brewery construction projects

- Brewery upgrades and retrofits

- Fermentation control systems

- Distillation control systems

- Packaging control systems

Knowledge Hubs

Balance your Project forecast to Human Capital ratio using our services,

14+ Years of Global Engineering Expertise

160+ Successfully Completed Projects

Support on EVERY Automation OEM Platform

Right from Site Survey, Design Engineering, to FAT, SAT & Post SAT Suppport