SIL verification in exSILentia software & SRS documentation preparation for one of the leading EPC from Texas USA

SIL verification in exSILentia software & SRS documentation preparation for one of the leading EPC from Texas USA

Scope of Work :

- SIF list Preparation,

- SIL Verification in exSILentia software,

- PIU Verification,

- Input Checklist Preparation,

- Logic Solver Checklist,

- Output checklist Preparation,

- Final Element Checklist,

- Review of PHA Report,

- Review C&E Report,

- Review Functional Logic diagram Report,

- Safety Manual Report,

- SRS Test Report Preparation,

- QC of all reports.

Platform: ExSILentia software

Instrumentation SIL 3 Consultancy for Oil & Gas – Ensuring Safety & Reliability

In the high-stakes environment of the oil and gas industry, safety and reliability are not just operational goals; they are fundamental imperatives. The potential for hazardous events necessitates robust safety instrumented systems (SIS) that can effectively mitigate risks. At iPAC Automation, we provide specialized Instrumentation Safety Integrity Level (SIL) 3 Consultancyservices tailored to the unique demands of the oil and gas sector. Our expertise empowers organizations to achieve the highest levels of safety integrity, ensuring the protection of personnel, the environment and assets.

Understanding SIL 3: Achieving the highest level of safety integrity, SIL 3, demands meticulous planning, rigorous analysis and precise implementation. It signifies a system with a very low probability of dangerous failure on demand (PFD). For oil and gas facilities, where complex processes involve flammable materials and high pressures, achieving and maintaining SIL 3for critical safety functions is paramount for preventing catastrophic incidents.

Our comprehensive Instrumentation SIL 3 Consultancyservicesencompass the entire safety lifecycle, as defined by IEC 61508 and IEC 61511 standards. We work collaboratively with your engineering teams to provide the following:

Hazard and Risk Assessment: Our experienced consultants conduct thorough hazard identification (HAZID) studies and risk assessments to pinpoint potential hazards and evaluate their associated risks. This foundational step is crucial for defining the safety functions and the required SIL.

Safety Requirements Specification (SRS): Based on the risk assessment, we develop a detailed SRS document that clearly outlines the functional safety requirements, performance criteria (including Safety Integrity Levels) and operational and maintenance procedures for your SIS. This document serves as the blueprint for the design, implementation and verification of your safety systems.

SIL Verification and Validation: Our team employs proven methodologies to verify that the design and implementation of your safety instrumented functions (SIFs) meet the target SIL 3 requirements. This includes Probability of Failure on Demand (PFD) calculations, fault tree analysis and Failure Modes, Effects and Diagnostic Analysis (FMEDA) to quantify the reliability and availability of your safety loops. We also conduct rigorous validation activities to ensure that the implemented SIS performs as intended in the actual operating environment.

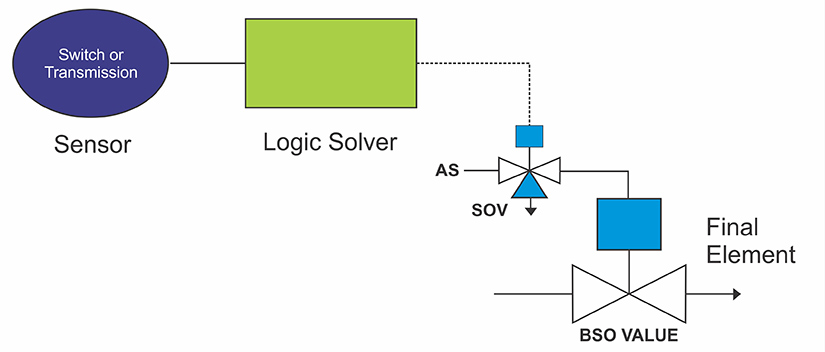

Safety Instrumented System (SIS) Design and Engineering Support: Leveraging our deep understanding ofinstrumentation and control systems, we provide expert guidance on the design and engineering of your SIS to ensure compliance with SIL 3 requirements. This includes the selection of appropriate safety-rated devices (sensors, logic solvers and final elements) and the implementation of robust architectures.

Functional Safety Assessment (FSA): We conduct independent FSAs at various stages of the safety lifecycle to ensure that the necessary activities have been carried out competently and that the evidence demonstrates the suitability of the safety systems for the intended application and SIL.

Proof Testing and Maintenance Procedures: Developing effective proof testing and maintenance procedures is vital for maintaining the required SIL over the lifetime of the SIS. Our consultants assist in creating detailed procedures and schedules to ensure the ongoing integrity and availability of your safety functions.

Competency Building and Training: We offer specialized training programs to enhance the functional safety competency of your personnel. These programs cover the principles of IEC 61508/61511, SIL determination, verification and validation, empowering your team to effectively manage and maintain your safety systems.

Why Choose iPAC Automation for SIL 3 Consultancy in Oil & Gas?

- Deep Industry Expertise: Our consultants possess extensive experience working with clients across the oil and gas sector in India, USA and UAE, understanding the specific safety challenges and regulatory requirements in these regions.

- Certified Professionals: Our team includes certified functional safety experts (CFSE) with a proven track record in delivering high-integrity safety solutions.

- Independent and Objective: We provide impartial and objective assessments and recommendations, ensuring the integrity and effectiveness of your safety systems.

- Comprehensive Approach: We offer end-to-end consultancy services covering the entire safety lifecycle, providing consistent support from initial hazard identification to ongoing maintenance.

- Commitment to Safety Excellence: Our primary focus is on helping you achieve and maintain the highest standards of safety, protecting your people, environment and assets.

Partner with iPAC Automation to ensure the safety and reliability of your oil and gas operations with our expert Instrumentation SIL 3 Consultancy services. Contact us today to discuss your specific needs and how we can help you achieve operational excellence through functional safety.