Inspection, Commissioning & site support for WTP From Oman Project Details

Scope of Work :

- Pre-FAT.

- Cabinet Inspection as per the Layout Drawings

- Hardware checking

- Wiring Checking &Testing

- Cold loop Checking

- Hot loop Checking

- Functional loop testing

Platform: ML200R, C300 & EPKS

Ensuring Operational Excellence: Expert Inspection & Commissioning for Your WTP Plant

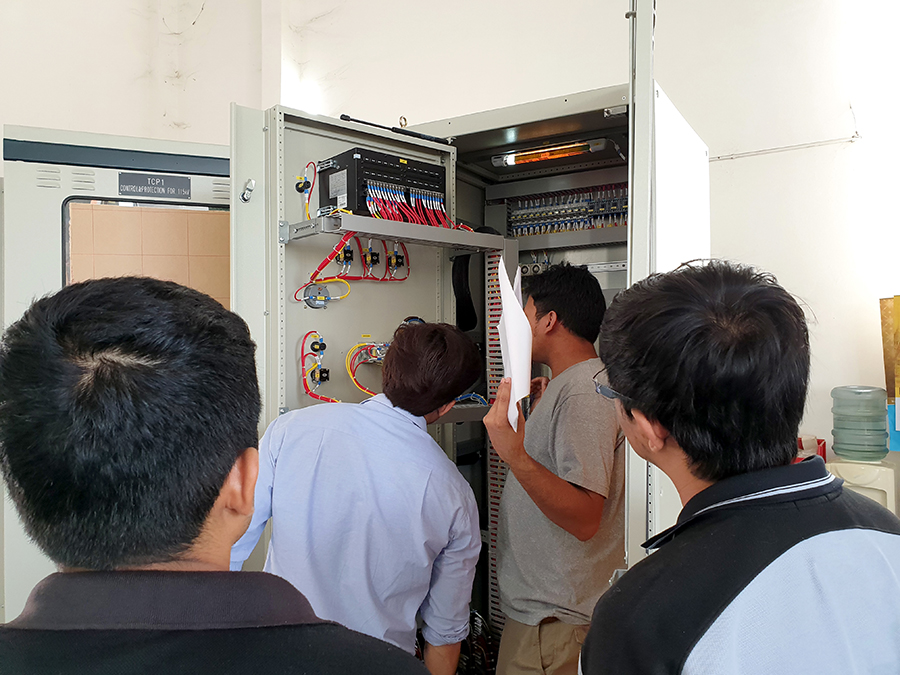

The successful launch and long-term reliability of any Water Treatment Plant (WTP) hinges on meticulous inspection and precise commissioning. At iPAC Automation, we specialize in delivering comprehensive site support, ensuring that every component of your control system performs exactly as intended from day one. Our expertise extends globally, as demonstrated by our dedicated support for a crucial WTP plant in Oman.

We understand that even the most advanced designs require thorough validation in the field. Our structured approach to inspection and commissioning safeguards your investment, minimizes startup delays and confirms the integrity of your entire automation infrastructure. Trust iPAC to transform your complex control system into a fully operational and reliable asset.

Our Rigorous Inspection & Commissioning Process:

Our commitment to perfection is evident in every phase of our site support. For the WTP in Oman, our detailed scope of work covered:

- Pre-FAT (Factory Acceptance Test) Preparation: We begin long before physical installation, ensuring all documentation, logic and hardware readiness are verified. This crucial pre-check helps to significantly reduce potential issues and streamlines the on-site commissioning efforts, saving valuable time and resources.

- Cabinet Inspection as per Layout Drawings: Our experienced engineers meticulously inspect control cabinets against approved layout drawings. This verifies that all components are correctly placed, securely mounted and conform to design specifications, ensuring physical integrity and ease of maintenance.

- Hardware Checking: Every piece of hardware within the control system is thoroughly examined. This includes verifying part numbers, serial numbers and proper installation of controllers, I/O modules, power supplies and network devices, confirming all elements meet project requirements.

- Wiring Checking & Testing: We conduct comprehensive checks on all internal and external wiring. This involves verifying correct termination, proper labeling and continuity, preventing electrical faults and ensuring reliable signal transmission throughout the system.

- Cold Loop Checking: This critical step involves verifying the entire loop from field instrumentation to the control system without applying power to field devices. We confirm correct wiring continuity, signal path integrity and proper instrument calibration settings, detecting errors early.

- Hot Loop Checking: Once cold loop checks are complete, we power up the loops and verify live signal readings. This confirms that all field instruments, transmitters and control valves are communicating accurately with the control system, validating real-time data acquisition.

- Functional Loop Testing: The final stage involves comprehensive functional testing of each control loop. We simulate various operating conditions to confirm that the system logic, interlocks and control actions perform precisely as per the process control philosophy, ensuring optimal plant operation.

The iPAC Advantage: Reliability from Oman to Anywhere

Our meticulous approach to inspection, commissioning and site support ensures that your Water Treatment Plant’s automation system operates with maximum efficiency and accuracy. By partnering with iPAC Automation, you gain:

- Early detection and resolution of potential issues, avoiding costly delays.

- Confirmed system integrity and adherence to design specifications.

- Reduced risks during plant startup and ongoing operations.

- A fully validated and reliable control system for consistent performance.

Ensure Your WTP Operates with Precision.

Don’t leave your plant’s reliability to chance. Our proven processes and global experience mean your Water Treatment Plant receives the highest standard of inspection and commissioning.

Schedule Your Plant Commissioning Support | Request an Inspection Quote