PLC/DCS System Implementation Services

If your process plant needs to implement planned process automation systems like Programming Logic Controller (PLC), Supervisory Control and Data Acquisition (SCADA), and Distributed Control Systems (DCS), look no further than iPAC Automation Pvt. Ltd. Our expert services cover engineering, supply, installation and testing/commissioning of automation systems.

We not only specialize in making inclusive automation plans according to the technical requirements of our clients but also in implementing these plans in an effective manner so as to improve the overall process control.

With years of industry experience and superior skills, experts at iPAC Automation have been performing trendsetting DCS/PLC/SCADA Implementation work for quite a few years now.

We take special care to understand the technical needs of our clients, as well as their budget requirements, and carry out all planning and implementation work, communicating closely with the technical personnel of the company all the time.

We also consider various facets of DCS/PLC/SCADA Implementation such as detailing, design, FAT, SAT, Commissioning

- Developing functional design specifications & detailed design specifications inherent to DCS/ PLC/SCADA Implementation and making comprehensive procedure plans

- Designing custom control panels including system panels and marshaling panels

- Creating plan diagrams for the distribution of power for instruments, which includes making a database of the wiring system and its layout

- Generation of plant logic from C&E, Narratives, and process detail.

- Customized Screen development of SCADA /HMI from P&ID.

- Third-party communication.

- Detailed instrument loop diagrams.

As is apparent, we at iPAC Automation Pvt. Ltd. are technically equipped and are enriched with significant experience to handle all your DCS/PLC/SCADA Implementation needs.

For comprehensive process automation systems, iPAC Automation Pvt. Ltd. is your trusted partner. With expertise in PLC, SCADA, and DCS implementation, we engineer, supply and test automation solutions.

Our trendsetting work in DCS/PLC/SCADA implementation is backed by years of industry experience. We meticulously design inclusive automation plans, tailored to your technical requirements and budget.

From detailed design to FAT, SAT, and commissioning, iPAC Automation handles every facet of implementation, delivering optimized process control. Choose iPAC Automation for reliable, efficient, and cost-effective automation solutions.

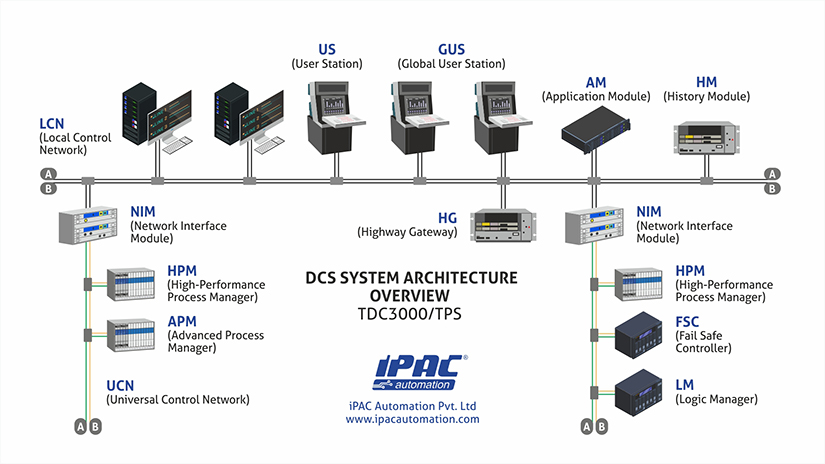

What is DCS Implementation?

DCS or distributed control system is a control ssrem for a process plant where autonomous controllers are distributed throughout the system. It uses a centralized supervisory control loop to mediate a group of localized controller.

By implementing DCS, businesses can enhance operational efficiency, improve process control, and optimize productivity.

Examples of PLC/DCS System Implementation services include

- developing design specifications,

- custom control panel design,

- power distribution planning,

- logic generation,

- SCADA/HMI development,

- communication integration,

- instrument loop diagrams,

- testing, and ongoing support.

iPAC Automation’s PLC/DCS System Implementation Services Include

Here are the PLC/ DCS system Implementation Services that iPAC can help you with.

1. Precise and Reliable System Design:

Trust iPAC Automation to develop flawless Functional Design Specifications and Detailed Design Specifications for your DCS/PLC, ensuring optimal performance and accuracy.

2. Customized Control Panels:

Our expert team specializes in designing bespoke control panels, including System Panels and Marshalling Panels, offering seamless integration and enhanced operational control.

3. Efficient Power Distribution:

iPAC Automation creates comprehensive plan diagrams for the efficient distribution of power to instruments, ensuring seamless functionality and uninterrupted operations.

4. Seamless Logic Generation:

With iPAC Automation, experience effortless generation of plant logic from Control & Execution (C&E), Narratives, and process details, ensuring precise automation and streamlined processes.

5. Intuitive SCADA/HMI Development:

iPAC Automation excels at developing customized screens for SCADA/HMI systems based on Piping and Instrumentation Diagrams (P&ID), providing a user-friendly and intuitive interface for monitoring and control.

6. Enhanced Communication Capabilities:

Trust iPAC Automation for seamless third-party communication integration, enabling efficient data exchange and interoperability across your automation ecosystem.

7. Comprehensive Instrument Loop Diagrams:

iPAC Automation offers detailed Instrument Loop Diagrams, providing a clear visualization of instrument connections and ensuring accurate control and monitoring.

Our Approach to PLC/DCS System Implementation Services And Support

After providing PLC/DCS services for over 15 years, this is the approach we have developed to provide with optiuk results.

- Consultation and Requirement Gathering: Our expert team of automation engineers will engage in in-depth consultations to understand your specific requirements and objectives.

- Design and Specification Development: Leveraging our extensive expertise, we will develop detailed Functional Design Specifications (FDS) and Detailed Design Specifications (DDS) specific to your DCS/PLC requirements.

- Custom Control Panel Design: Our skilled professionals will design custom control panels, including System Panels and Marshalling Panels, precisely tailored to your unique automation needs.

- Power Distribution Planning: iPAC Automation will create comprehensive plan diagrams that efficiently distribute power to your instruments.

- Logic Generation and SCADA/HMI Development: Building upon Control & Execution (C&E) documents, narratives, and process details, we will generate customized screens for SCADA/HMI systems based on Piping and Instrumentation Diagrams (P&ID).

- Seamless Communication Integration: iPAC Automation excels in integrating third-party communication capabilities, enabling efficient data exchange and interoperability across your automation ecosystem.

- Detailed Instrument Loop Diagrams: Our engineers will create comprehensive Instrument Loop Diagrams, providing clear visualizations of instrument connections and facilitating accurate control and monitoring.

- Testing and Commissioning: Once the system is fully implemented, our team will conduct thorough testing and commissioning to ensure optimal performance and reliability.

- Ongoing Support and Maintenance: iPAC Automation remains committed to your success even after system implementation. We offer comprehensive support and maintenance services to ensure your PLC/DCS system operates at peak efficiency, minimizing downtime and maximizing productivity.

Different Types Of Industries We Serve With Our PLC/DCS System Implementation Services

iPAC Automation excels in providing PLC/DCS system implementation services across various industries. Here are specific examples showcasing our expertise in each sector:

1. Oil and Gas:

Experience the power of iPAC Automation’s instrumentation and automation solutions tailored for the oil and gas industry. Our PLC/DCS system implementation services optimize production, enhance safety, and improve operational efficiency.

2. Pharmaceutical:

We design and deploy automation solutions that ensure regulatory compliance, increase productivity, and enhance process control for pharmaceutical manufacturing processes.

3. Automotive:

Our expert team implements PLC/DCS systems that streamline production, improve quality control, and enable efficient manufacturing processes, giving you a competitive edge.

4. Water Treatment:

iPAC Automation specializes in PLC/DCS system implementation for water treatment facilities. Our solutions enable precise control over water treatment processes, ensuring optimal efficiency, accurate monitoring, and improved resource management.

5. Power Generation:

We develop and deploy automation solutions that enhance control, efficiency, and reliability, enabling you to meet energy demands effectively.

6. Brewery:

iPAC Automation caters to the unique needs of the brewery industry. Our PLC/DCS system implementation services provide seamless automation for brewery processes, optimizing brewing operations, ensuring consistency in quality, and enhancing production efficiency.

Contact us today to discuss your specific requirements.