Smartplant instrumentation (SPI) services | SPI InTools Training

iPAC offers solutions as services on one of the most important instrumentation engineering tools SmartPlant Instrumentation (SPI). The identical program was formerly called Intools.

Engineering, Procurement, and Construction (EPC) Projects employ this software as a single, widely-used instrumentation application. Accessing and upgrading the instruments used in any plant for various duties is made easier by smart plant instrumentation.

| 1 | P & ID |

| 2 | Instrumentation index |

| 3 | I/O List |

| 4 | Preparing PT, FT,LT, TT,CV, MOV, XV, DCS, PLC (ESD-PLC), etc datasheet |

| 5 | Flow Calculations and Sizing of Control valves, Orifice plates & PSV |

| 6 | Material Requisition |

| 7 | Technical Bid Evaluation |

| 8 | Purchase Requisition |

| 9 | Vendor Document Review |

| 10 | Wiring diagram: A) Loop Wiring B) Junction Box Wiring C) E & I Interface D) Instrument Hook-up |

| 11 | Cable junction Schedule |

Smartplant Instrumentation (SPI) services and SPI Intools Training

iPAC’s SPI services encompass the implementation and utilization of the Smartplant Instrumentation software. This involves leveraging SPI’s capabilities to enhance data management, engineering efficiency, and collaboration throughout the instrumentation lifecycle.

Contact our experts and learn more about our SPI services.

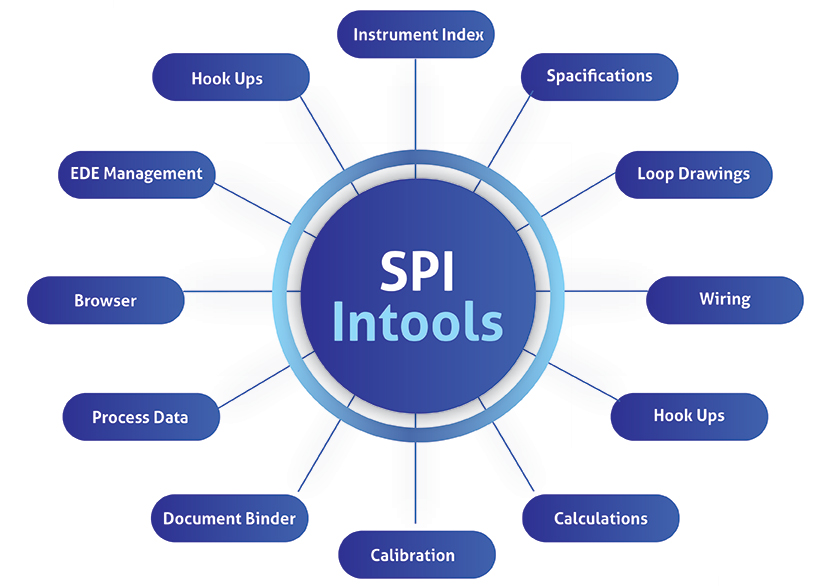

What are Smart Plant Instrumentation (SPI) Intools?

Smart Plant Instrumentation (SPI) Intools is a software application developed by Hexagon PPM (formerly known as Intergraph Corporation) specifically for instrumentation engineeringand design in the process industry.

SPI Intools is a comprehensive solution that enables engineers and designers to efficiently create, manage, and maintain instrumentation and control systems throughout the entire plant lifecycle.Key features of SPI intools include:

- Instrument Index

- Instrument Specification Sheets

- Instrument Data Sheets

- Instrument Loop diagrams

- Instrumentation Detailed Engineering

iPAC Automation’s SPI Services Includes

Here’s a brief list of services you can avail of at iPAC automations.

1. Instrumentation index

iPAC’s Instrumentation Index service empowers you with a centralized database for efficient instrument identification and management. You can easily access critical information such as instrument tags, descriptions, and specifications by creating and maintaining an accurate and up-to-date index.

2. I/O List

With iPAC’s I/O List service, you benefit from comprehensive documentation of all inputs and outputs required for their control system. Our experts meticulously identify and document the necessary I/O points, ensuring accurate communication and integration between field instruments and the control room.

3. Preparing PT, FT, LT, TT, CV, MOV, XV, DCS, PLC (ESD-PLC) datasheet

These datasheets include specifications, performance parameters, and technical details necessary for instrument selection, installation, and configuration.

By relying on iPAC’s expertise, you can ensure your instrumentation’s reliable and optimal performance. And control systems while minimizing errors, and enhancing system integrity, thus, improving overall plant productivity.

4. Flow Calculations and Sizing of Control valves, Orifice plates & PSV

iPAC’s service for flow calculations and sizing of control valves, orifice plates, and pressure safety valves (PSV) ensures the accurate and optimal performance of these critical components.

Our experts utilize industry-standard methods and advanced tools to calculate and determine the appropriate sizes for control valves, orifice plates, and PSVs based on specific flow requirements and process conditions.

5. Material Requisition

With iPAC’s Material Requisition service, you can efficiently procure the necessary materials for their field instruments and related components.

Our experts assist in preparing comprehensive material requisitions, specifying the types, quantities, and specifications of the required materials.

This will help you optimize your instrument procurement, facilitating smoother project execution and timely delivery of material.

6. Technical Bid Evaluation

iPAC’s Technical Bid Evaluation service helps you assess and compare technical proposals from instrument vendors.

Our experts meticulously evaluate the bids based on predetermined criteria and project requirements.

This service ensures that you are receiving high-quality and reliable instruments that align with their technical specifications, leading to successful project outcomes and optimized performance of the instrumentation system.

7. Purchase Requisition

Our Purchase Requisition service enables customers to initiate the procurement process for field instruments effectively. Our experts assist in generating comprehensive purchase requisitions that detail the required instruments, quantities, and specifications.

A well-prepared purchase requisition is crucial for smooth communication with vendors, reducing the risk of errors or misunderstandings, and ensuring that the right instruments are procured for the project.

With iPAC you get minimum delays and efficient procurement.

8. Vendor Document Review

iPAC’s Vendor Document Review service, you get a comprehensive evaluation of documents submitted by instrument vendors. Our experts meticulously review vendor-provided drawings, specifications, and other technical documents to ensure project requirements and industry standards compliance.

So chances of errors and delays are less, and you maintain the project integrity successfully.

9. Wiring diagram

With iPAC’s Wiring Diagram service, you can benefit from comprehensive and accurate documentation of electrical wiring connections for your field instruments. Our experts meticulously create a variety of wiring diagrams like loop wiring, junction box wiring, E & I interface, and instrument hookups.

By utilizing iPAC’s Wiring Diagram service, you can ensure efficient and error-free wiring, reducing the risk of electrical issues and optimizing the performance of your instrumentation system.

10. Cable junction Schedule

iPAC’s Cable Junction Schedule service provides you with a comprehensive schedule that details the locations and specifications of cable junctions within your instrumentation system.

With our Cable Junction Schedule service, you can efficiently plan and organize the routing and termination of cables, ensuring proper connections and reducing the risk of errors.

Our approach to Smartplant instrumentation and Smartplant Intools

Here are some vital steps in iPAC’s smart plant instrumentation and smart plant in tools services.

- Preparation of instrument index

- Preparation of IO List

- Curation instrumentation data specification sheet

- Handling material requisition for field instrument

- Conducting technical bid evaluation for field instrument

- Purchasing requisition for field instrument

- Vendor drawing review and coordinating

- Making hook-up drawings

- Instrument location layout designing

- Managing SPI/INTOOLS for integrated data

- Providing instrument calibration services

- Instrument erection supervising

Industries Served by iPAC’s Smart Plant InstrumentationIndustries We Serve

With over 15 years in service, iPAC has served some of the major industries around the globe. Some of the notables include:

1. Oil and Gas

iPAC has closely worked with SPI (Safety and Process Improvement) services in the oil and gas industries, from designing and detailing to controlling and commissioning.

Our expertise in SPI services has provided us with a profound knowledge of the distinct challenges and safety regulations associated with oil and gas operations.

2. Brewery

iPAC has also provided tailored and comprehensive SPI services for the brewery industry. Our services included designing and optimizing safety protocols, streamlining production processes, implementing efficient quality control measures, and ensuring compliance with industry regulations.

Through our expertise in SPI, we have helped breweries enhance their operational safety, increase productivity, and maintain the highest standards of quality in their brewing processes.

3. Power Generation

PAC has been instrumental in delivering specialized SPI (Safety and Process Improvement) services designed for the power generation industry.

We have extensive experience in this sector, offering a range of services that include assessing and enhancing safety protocols, optimizing operational efficiency, implementing preventive maintenance strategies, and ensuring compliance with stringent industry regulations.

4. Water Treatment

iPAC has a proven track record of providing exceptional SPI (Safety and Process Improvement) services in the water treatment industry.

Apart from designing and implementing safety protocols we offer customized solutions that address the unique challenges faced by water treatment facilities, such as maintaining water quality, optimizing chemical usage, and improving operational efficiency.

5. Pharma

In pharma industry, we assist manufacturers in implementing safety protocols, optimizing processes, and ensuring regulatory compliance. Our expertise helps streamline operations, improve product quality, and enhance patient safety.

6. Automotive

At iPAC Automation, we have collaborated with clients in the automotive industry around the glove, emphasizing the significance of SPI (Safety and Process Improvement) services. Our focus lies in ensuring that our safety systems align with industry standards and regulatory requirements.

Why choose iPAC Automation for your Smartplant instrumentation engineering services

1. Expertise and Experince

iPAC Automation has experience of working on over 160 projects and has a footprint on 11+ countries. Not only that but despite having such large and versatile cutomer base we have successfully retained a 100% customer satisfaction rate.

2. Proven Maethodologies and Approach

iPAC as an SPI service provider has well-defined m methodologies and approaches that we apply consistently across our different projects. We have a structured systematic approach for safety and process improvement, that can be tailored to each client’s specific needs.

3. Collaboration With Indutry Leaders

iPAC has collaborated with some of the biggest names such as Simens, Mitsubhishi Electric, Emerson, Honeywell. Schneider electric, Thermax, Larsen & Tourbo. Johnson Controls and many more.

Contact our expertsand get a quote for your smartplant instrumentation services.

iPAC offers following services for SPI

| 1 | P & ID |

| 2 | Instrumentation index |

| 3 | I/O List |

| 4 | Preparing PT,FT,LT,TT,CV,MOV, XV, DCS, PLC (ESD-PLC) etc datasheet |

| 5 | Flow Calculations and Sizing of Control valves, Orifice plates & PSV |

| 6 | Material Requisition |

| 7 | Technical Bid Evaluation |

| 8 | Purchase Requisition |

| 9 | Vendor Document Review |

| 10 | Wiring diagram: A) Loop Wiring B) Junction Box Wiring C) E & I Interface D) Instrument Hook-up |

| 11 | Cable junction Schedule |