Safety Integrity Level (SIL) verification services

Right from Reviewing the PHA report to the preparation of the SIF list to do the proper QC check of the SIF list, Input/Output/Logic Solver Checklist and Compliance Reports iPAC provides error-free SIL verification services for ESD systems which includes

| Sr. No. | Service type |

|---|---|

| 1 | SIF list Preparation, |

| 2 | SIL Verification in exSILentia software, |

| 3 | PIU Verification, |

| 4 | Input Checklist Preparation, |

| 5 | Logic Solver Checklist, |

| 6 | Output checklist Preparation, |

| 7 | Review of PHA Report, |

| 8 | Review C&E Report, |

| 9 | Review Functional Logic diagram Report, |

| 10 | Safety Manual Report, |

| 11 | SRS Test Report Preparation, |

| 12 | QC of all reports. |

iPAC Automation is involved in evaluating, verifying, and validating equipment and processes’ safety integrity levels (SIL), ensuring we meet industry standards and regulatory requirements for safe and reliable operation.

Request a quote for SIL verification services for the USA, UK, and other European countries.

What is SIL Verification?

SIL verification is the process of assessing safety systems in hazardous industries to confirm we have the appropriate level of safety integrity.

This involves evaluating safety functions, reliability, and performance to determine SIL rating. Verification is essential to ensure systems are designed and implemented correctly, meeting industry standards and regulatory requirements for safe operation.

What are the methods of SIL Verification?

Various methods are used to verify SIL, including:

- Hazard and Operability (HAZOP) Studies

- Safety Integrity Level (SIL) Assessments

- Fault Tree Analysis (FTA)

- Reliability Block Diagrams (RBD)

- Markov Analysis

- Bayesian Networks

- Petri Nets

- Layer of Protection Analysis (LOPA)

iPAC Automation’s approach to SIL verification

iPAC Automation follows a systematic and comprehensive approach to Safety Integrity Level (SIL) services, which involves the following steps:

- Understanding client requirements: iPAC Automation first works closely with our clients to understand their specific requirements, including the safety instrumented functions (SIFs) involved, the process hazards, and the desired SIL levels.

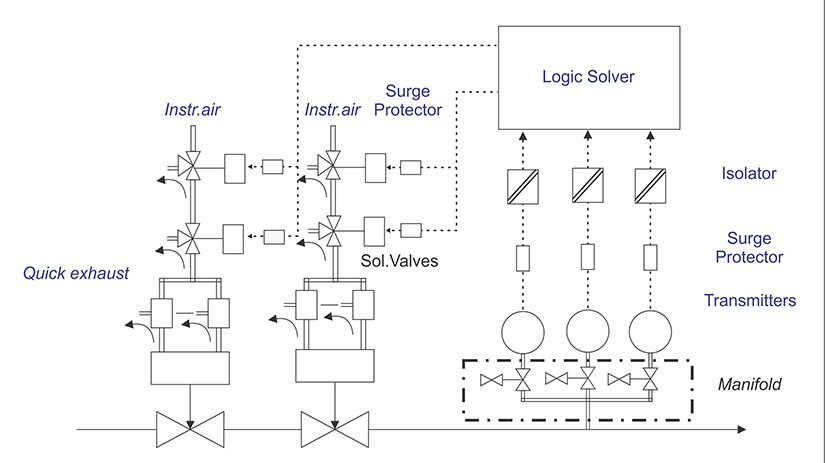

- Preparation of checklists: Once the requirements are understood, iPAC Automation prepares input, logic solver, and output checklists to ensure that all necessary information is collected and verified during the SIL verification process.

- SIL verification: iPAC Automation then performs SIL verification using advanced software tools such as exSILentia, which allows for accurate and reliable SIL analysis.

- Review of PHA and C&E reports: iPAC Automation reviews the Process Hazard Analysis (PHA) report and the Cause and Effect (C&E) report to ensure all hazards are identified and accounted for.

- Preparation of SRS test report: Once the SIL verification is complete, iPAC Automation prepares a Safety Requirements Specification (SRS) test report to document the results and demonstrate compliance with industry standards and guidelines.

- QC of all reports: Before submitting the final reports, iPAC Automation performs quality control (QC) to ensure that all information is accurate and complete.

Overall, iPAC Automation’s approach to SIL services is systematic, thorough, and tailored to meet its client’s specific needs and requirements.

Industries we serve

1. Oil and gas

iPAC Automation has worked with oil and gas industry clients, providing SIL verification and validation services to refineries, petrochemical plants, and offshore platforms. Our experience in this industry has given them a deep understanding of the unique challenges and safety requirements involved in oil and gas operations.

2. Power generation

iPAC Automation has experience working with power generation plants, including nuclear, fossil fuel, and renewable energy facilities. We understand the critical role of safety systems in ensuring these facilities’ reliable and safe operation.

3. Brewery

iPAC Automation has provided SIL verification and validation services to clients in the brewery industry, ensuring that our safety instrumented systems meet industry standards and comply with regulatory requirements. Our experience in this industry has given them an understanding of the unique challenges in ensuring brewing processes’ safety and reliability.

4. Water treatment

iPAC Automation has worked with clients in the water industry, including water treatment plants and distribution networks. Our experience in this industry has given them a deep understanding of the importance of safety systems in ensuring the reliable and safe supply of clean water.

5. Pharma

iPAC Automation has provided SIL verification and validation services to clients in the pharmaceutical industry, where safety and reliability are of utmost importance. We understand the critical role of safety systems in ensuring the quality and safety of pharmaceutical products.

6. Automotive

iPAC Automation has experience working with clients in the automotive industry, ensuring that our safety instrumented systems meet industry standards and comply with regulatory requirements.

Our Safety Integrity Level (SIL) Verification Service Types

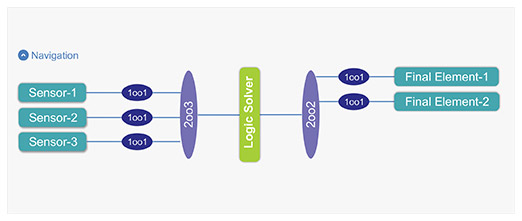

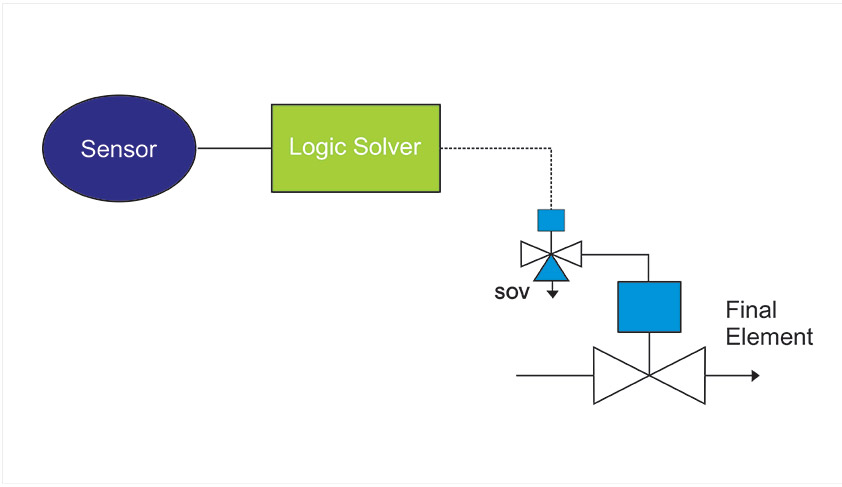

- Safety Instrumented Function (SIF) list Preparation: Creating a comprehensive list of safety instrumented functions for a process plant.

- SIL Verification in exSILentia software: Using specialized software to perform SIL verification and analysis of safety systems.

- PIU Verification: Evaluating the safety interface unit of a safety instrumented system to ensure it meets safety requirements.

- Input Checklist Preparation: Developing a checklist of requirements for inputs to a safety instrumented system.

- Logic Solver Checklist: Developing a checklist of requirements for the logic solver component of a safety instrumented system.

- Output checklist Preparation: Developing a checklist of requirements for outputs from a safety instrumented system.

- Review of the Process Hazard Analysis (PHA) Report: Reviewing the results of a structured approach for identifying potential hazards and risks associated with a process or system.

- Review C&E Report: Review a Cause and Effect report, which summarizes the interconnections between process inputs, outputs, and safety functions.

- Review Functional Logic Diagram Report: Review a report summarizing the logic and functionality of a safety instrumented system.

- Safety Manual Report: Creating a formal document outlining a process plant’s safety policies and procedures.

- Safety Requirements Specification (SRS) Test Report Preparation: Creating a formal document summarizing the results of testing the safety functions of a system or component against the requirements specified in the SRS.

- QC of all reports: Conduct quality control checks on all reports to ensure accuracy and completeness.

Our SIL verification services include:

iPac Automation is a reputable service provider specializing in SIL verification and validation services for process plants. Here are several reasons one may choose iPac Automation for our SIL verification and validation service requirements:

- Expertise: iPac Automation has a team of experienced and qualified engineers who are experts in SIL verification and validation. We are equipped with the necessary skills and knowledge to provide high-quality services that meet the specific requirements of our clients.

- Advanced tools: iPac Automation utilizes software tools such as exSILentia to perform SIL verification and analysis. These tools enable them to provide accurate and reliable results that ensure the safety and reliability of a process plant.

- Compliance: iPac Automation’s services comply with industry standards and guidelines, such as IEC 61511 and ISA 84. We ensure that our client’s safety instrumented systems meet the necessary safety requirements and comply with the applicable regulations.

Related services:

1. Instrumentation Detailing & Designing Services

2. PLC/DCS System Implementation Services